When planning to enter the compound fertilizer market, many investors first ask: what is the cost of a bulk blending fertilizer production plant? Compared with traditional granulation lines, a BB fertilizer production plant offers a cost-efficient, high-output solution, especially for regions with strong demand for customized NPK fertilizer formulas.

Bulk blending fertilizer, also known as BB fertilizer, dry bulk blended fertilizer, or physical mixed fertilizer, is produced by mechanically mixing different granular raw materials without chemical reactions. This simple process makes BB fertilizer plants attractive for cost-driven investors.

What Is a Bulk Blending Fertilizer Production Plant?

A bulk blending fertilizer production plant is designed to produce 10–50 tons per hour, focusing on accurate batching, uniform mixing, and fast packaging. Unlike drum granulation or roller compaction lines, BB fertilizer production does not require drying, cooling, or complex granulation systems.

This type of plant is often called a BB fertilizer manufacturing line, bulk blending NPK fertilizer plant, or dry blending fertilizer system. Learn more!

Typical Equipment Configuration

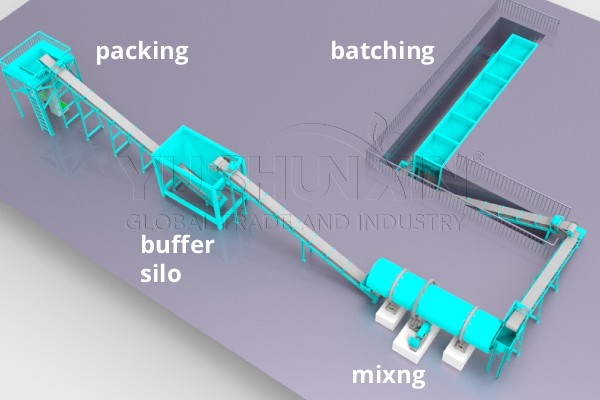

To control investment cost while maintaining production efficiency, a standard BB fertilizer production plant usually includes:

- Automatic batching system (belt scale or electronic weighing bins)

- Bulk blending fertilizer mixer (gravity mixer or rotary drum mixer)

- Material conveying system (belt or bucket conveyors)

- Finished fertilizer packing machine

- Optional dust collection system for environmental compliance

The equipment layout is compact, easy to operate, and suitable for fast installation. Inquiry YUSHUNXIN to get your own bb fertilizer production equipment!

How Much Does a BB Fertilizer Production Plant Cost?

The cost of a bulk blending fertilizer production plant typically ranges from USD 100,000 to USD 500,000, depending on capacity and automation level.

- 10–20 TPH BB fertilizer line: USD 100,000–250,000

- 30–50 TPH bulk blending plant: USD 300,000–500,000

Key cost factors include production capacity, weighing accuracy, automation degree, and packaging speed.

Why BB Fertilizer Plants Are Cost-Effective

Compared with granulated compound fertilizer production lines, BB fertilizer plants offer several economic advantages:

- Lower initial investment

- No drying or granulation energy consumption

- Reduced labor requirements

- Faster return on investment

This makes bulk blending fertilizer plants ideal for large distributors, regional fertilizer suppliers, and markets with flexible nutrient demand.

Output Capacity and Market Flexibility

With a capacity of 10–50 tons per hour, BB fertilizer production plants can quickly respond to seasonal fertilizer demand. By adjusting raw material ratios, producers can easily supply different NPK formulas to meet local soil requirements.

This flexibility significantly improves profit margins while keeping production costs under control.

Conclusion

For investors who prioritize cost efficiency and high output, a bulk blending fertilizer production plant is one of the most economical solutions in the compound fertilizer industry. With an investment range of USD 100,000–500,000, BB fertilizer manufacturing offers a practical balance between capacity, flexibility, and operating cost.

Choosing the right BB fertilizer equipment configuration is the key to maximizing returns while minimizing risk. If you need a business plan, welcome to visit: https://www.fertilizerequipmentprice.com/bulk-blending-fertilizer-line/